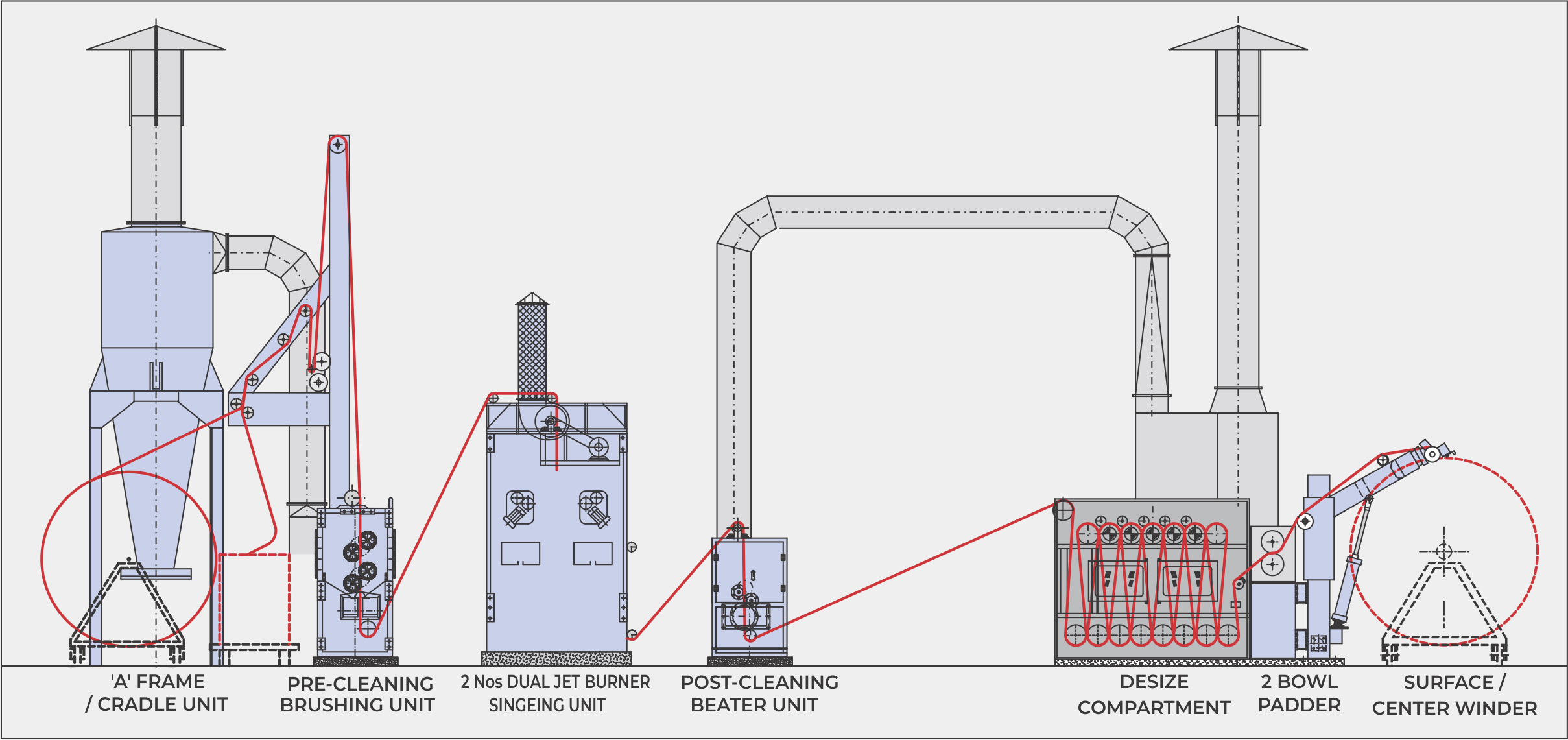

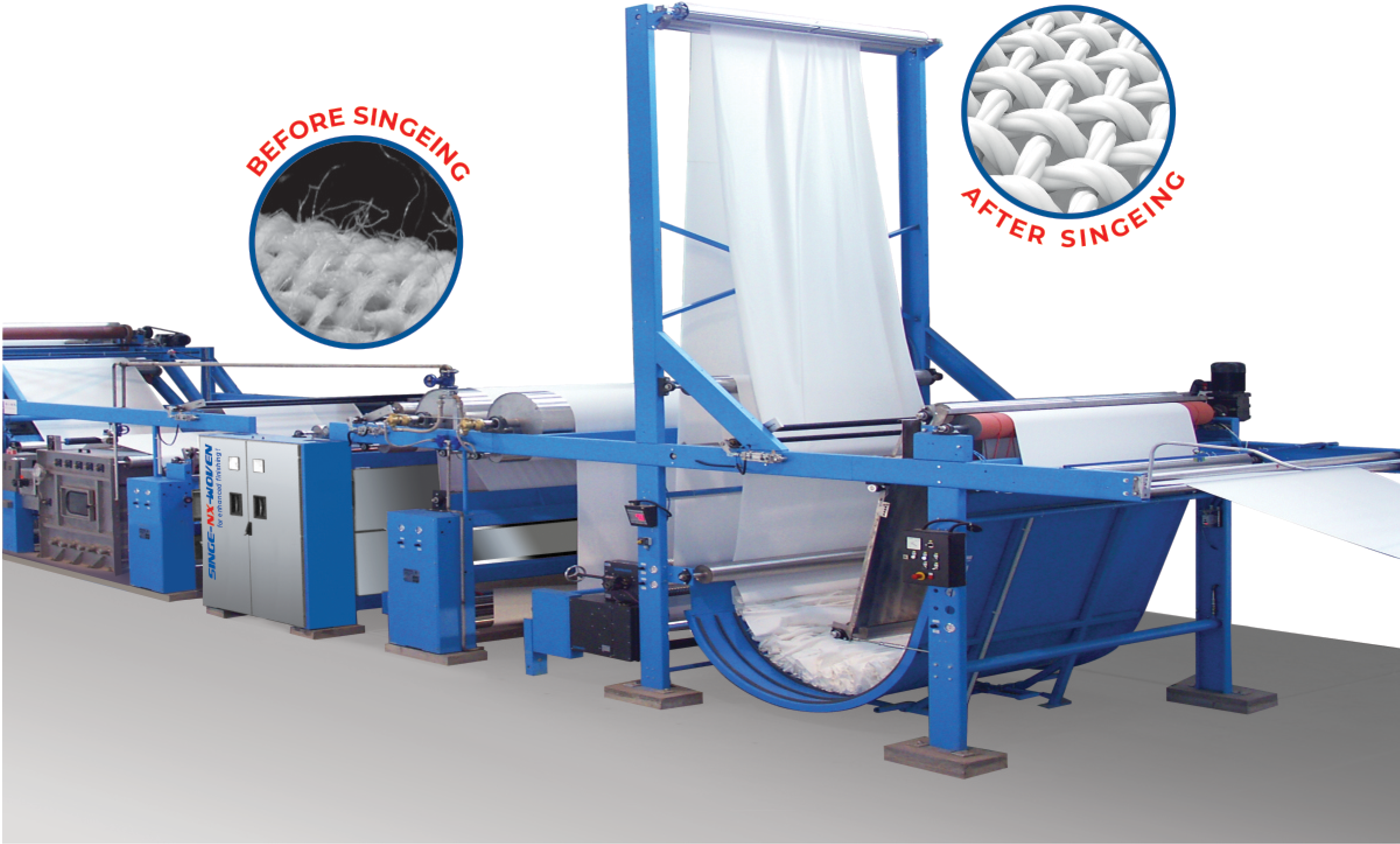

HIGH-EFFICIENCY SINGEING MACHINE FOR WOVEN FABRICS

WITH 2 (DUAL-JET) SINGEING BURNERS AND 4 SINGEING POSITIONS...

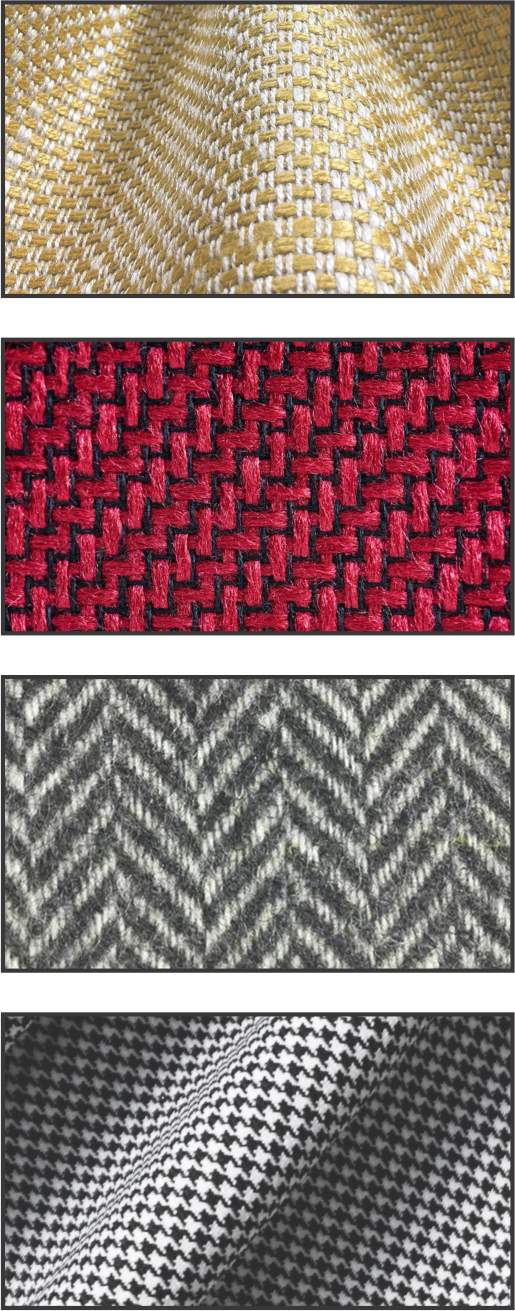

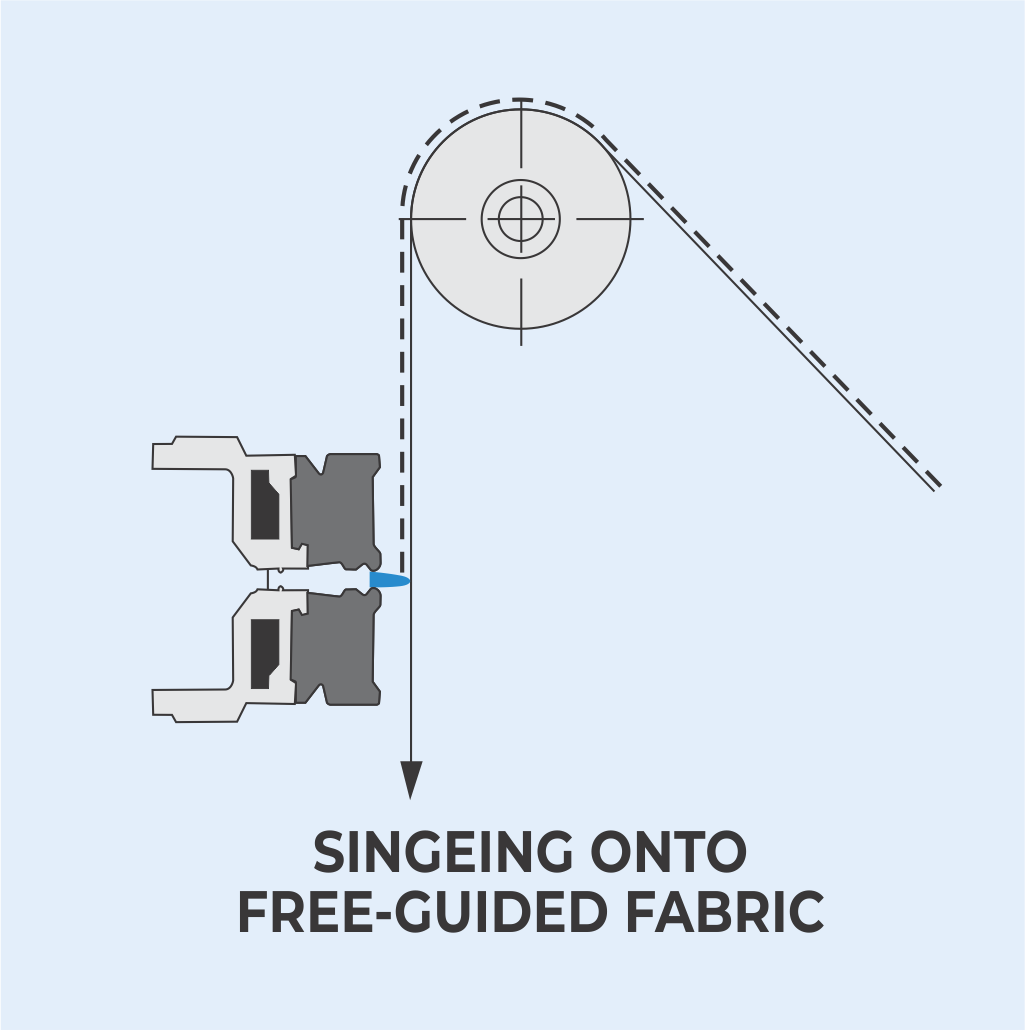

THE SINGEING FLAME MEETS THE FREE GUIDED FABRIC AT RIGHT ANGLES AS THE FABRIC PASSES BETWEEN TWO GUIDE ROLLERS. THE POSITION IS SUITABLE FOR 100% NATURAL FIBERS AND FOR BLENDED FABRICS WHICH HAVE BEEN THOROUGHLY BEATEN, WITH WEIGHTS OVER 125g/m².

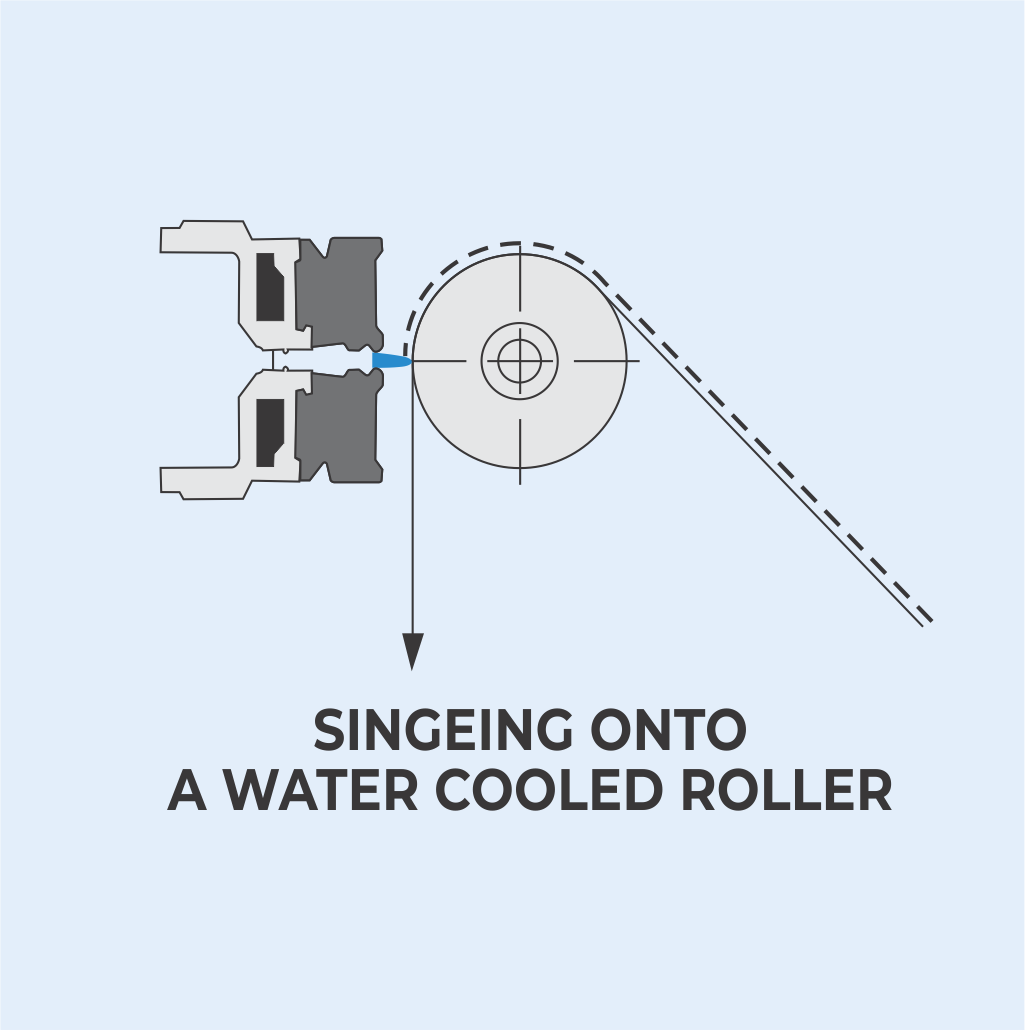

THE SINGEING FLAME MEETS AT RIGHT ANGLE ON TO THE FABRIC PASSING OVER A WATER COOLED ROLLER. THIS OPTION NORMALLY FOR QUALITY COMPOSED OF TEMPERATURE SENSITIVE FIBERS, OPEN-WEAVE BLENDED FABRICS AND THOSE WITH WEIGHTS OF LESS THAN 125g/m².

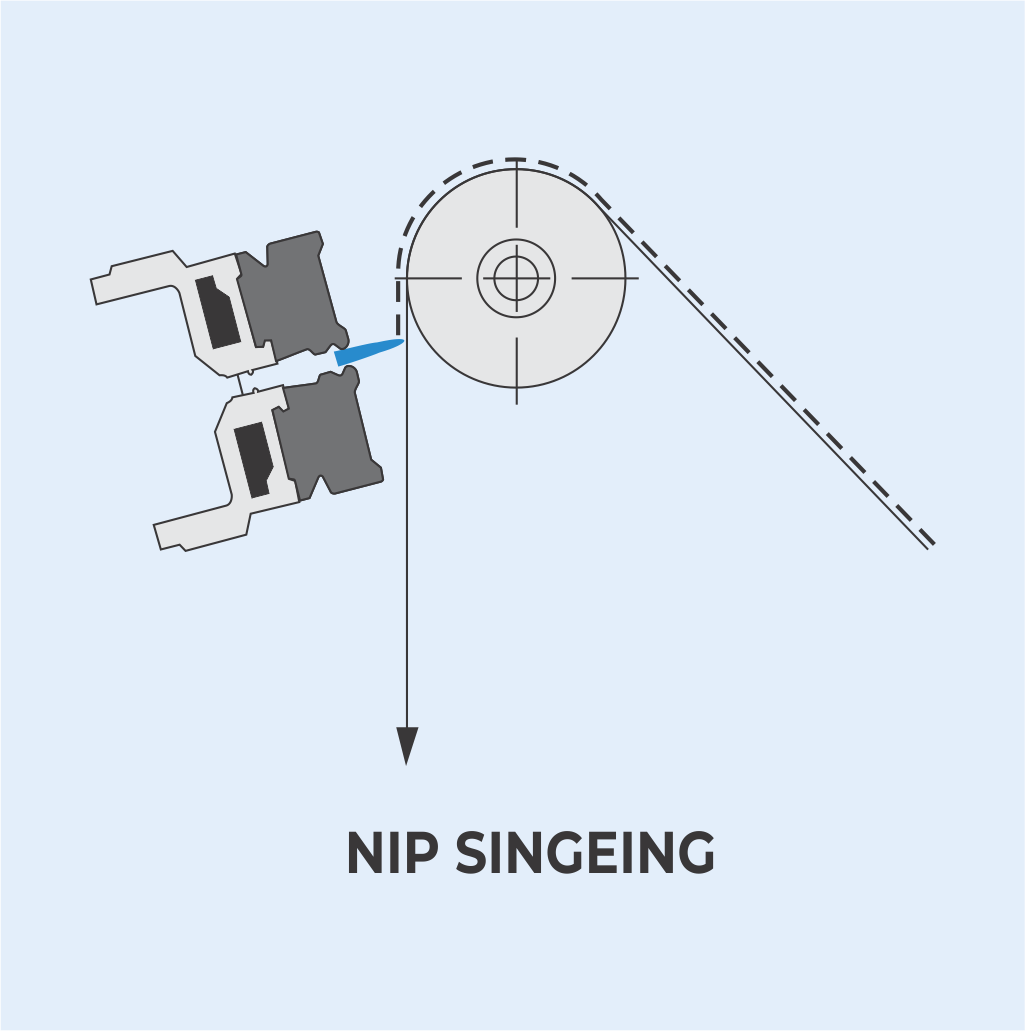

THE SINGEING FLAME CLOSE TO THE FABRIC, BUT JUST MISSING THE FABRIC SURFACE, SUITABLE FOR HEAVIER BLENDS OR HEAVIER SYNTHETIC FABRIC. THERE ARE OTHER PARAMETERS THAT INFLAME, IN ADDITION TO THE BURNER POSITION. (A) MACHINE SPEED. (B) FLAME INTENSITIES. (C) DISTANCE BETWEEN BURNER & FABRIC AND LASTLY (D) FABRIC TEMPERATURE.

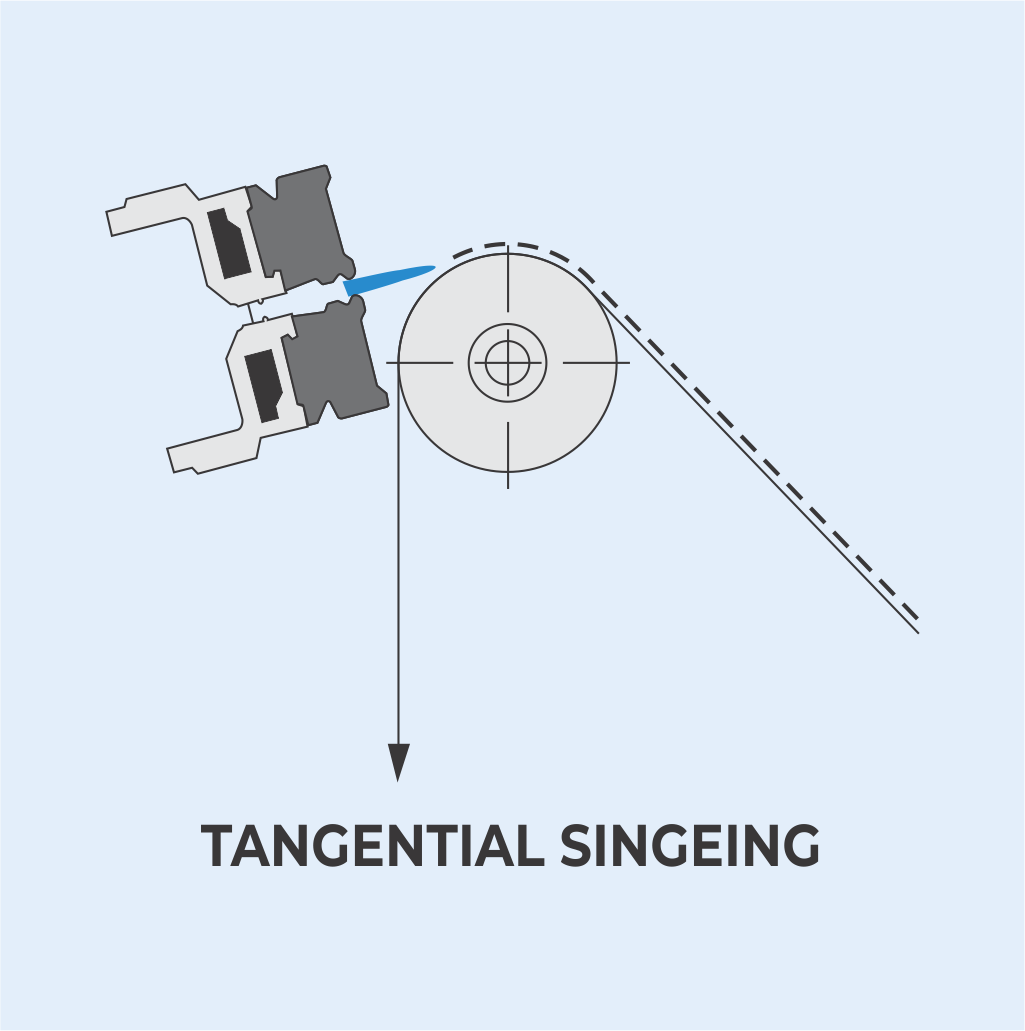

THE SINGEING PROCESS IS RECOMMENDED FOR ALL MATERIALS WHICH CANNOT TOLERATE DIRECT EXPOSURE TO FLAME. TANGENTIAL SINGEING CAN ALSO EQUALIZE PROTRUDING FIBERS AND REPAIR FILAMENT BREAKS.

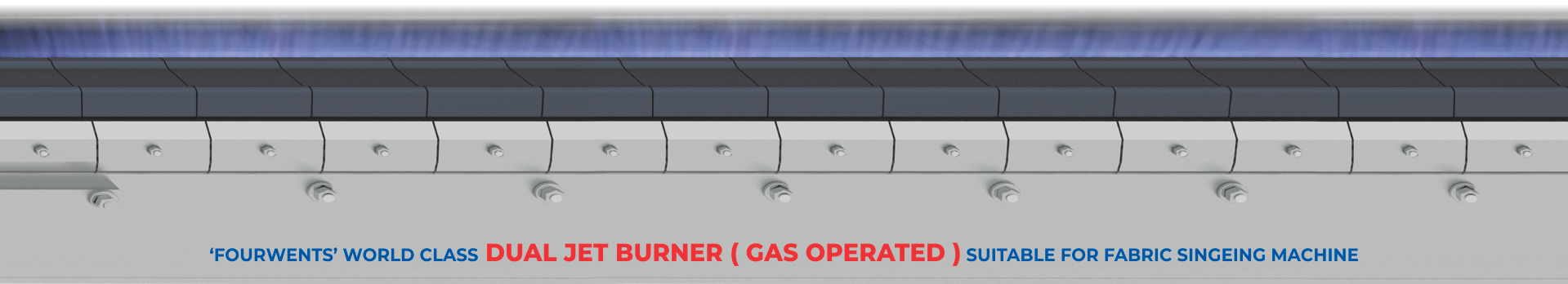

| HEATING MEDIUM | : LPG OR NATURAL GAS |

| FABRIC WIDTH | : 1600mm (WW) UPTO 3600mm |

| ROLLER WIDTH | : 2000mm UPTO 3600mm |

| MACHINE SPEED | : APPROX. 0TO 13 m/min |

| MIN. SINGEING SPEED | : 40m/min |

| WATER PRESSURE | : 2 TO 3 BAR |

| GAS PRESSURE | : 0.3 TO 3.0 BAR |

| COMPRASSED AIR | : 6 BAR |

| ELECTRIC VOLTEGE | : 400V, 3PHASE, 50HZ |