UNTIL RECENTLY, KNIT FABRIC FINISHING WAS FREQUENTLY DONE IN TUBULAR FORM. HOWEVER, THERE IS A STRONG TREND IN THE INDUSTRY TOWARD PROCESSING KNITS IN OPEN WIDTH FORM. THERE ARE SUBSTANTIAL ADVANTAGES AS WELL.

WHEN DISCUSSING QUALITY IMPROVEMENT, ALMOST QUICKLY SINGEING COMES TO THE ATTENTION OF THE SPECIALISTS ENGAGED. SINGE-NX, THE WORLD CLASS SINGEING MACHINES, HAS CREATED A NEW SINGEING MACHINE DESIGNED SPECIFICALLY FOR KNIT MATERIALS IN OPEN WIDTH FORM.

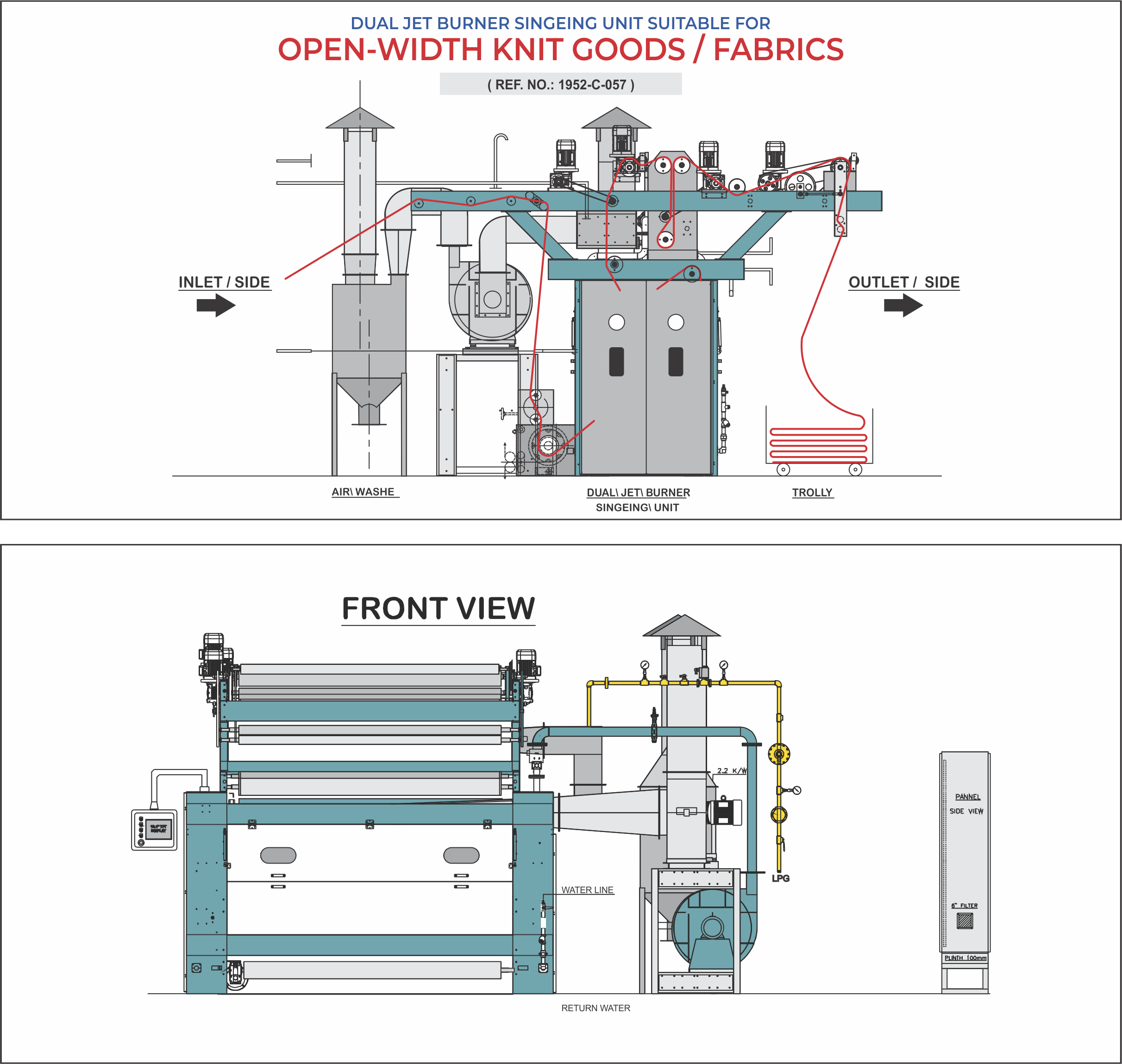

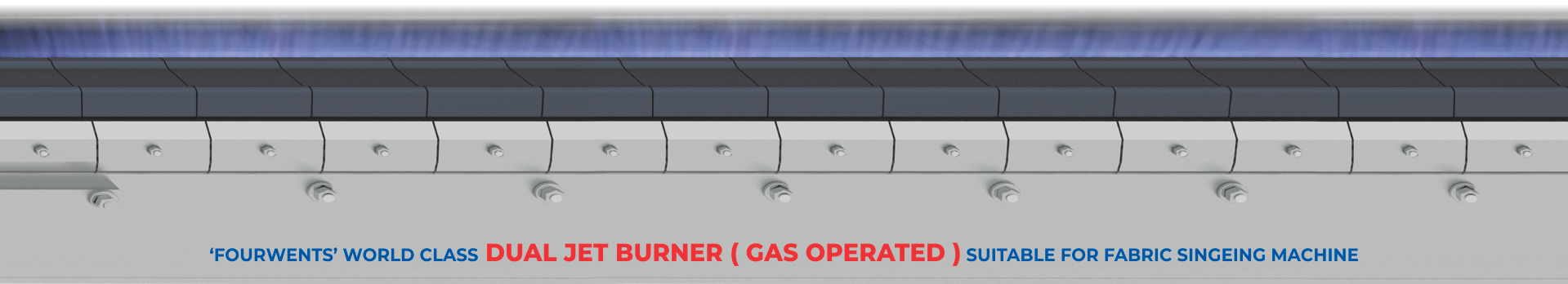

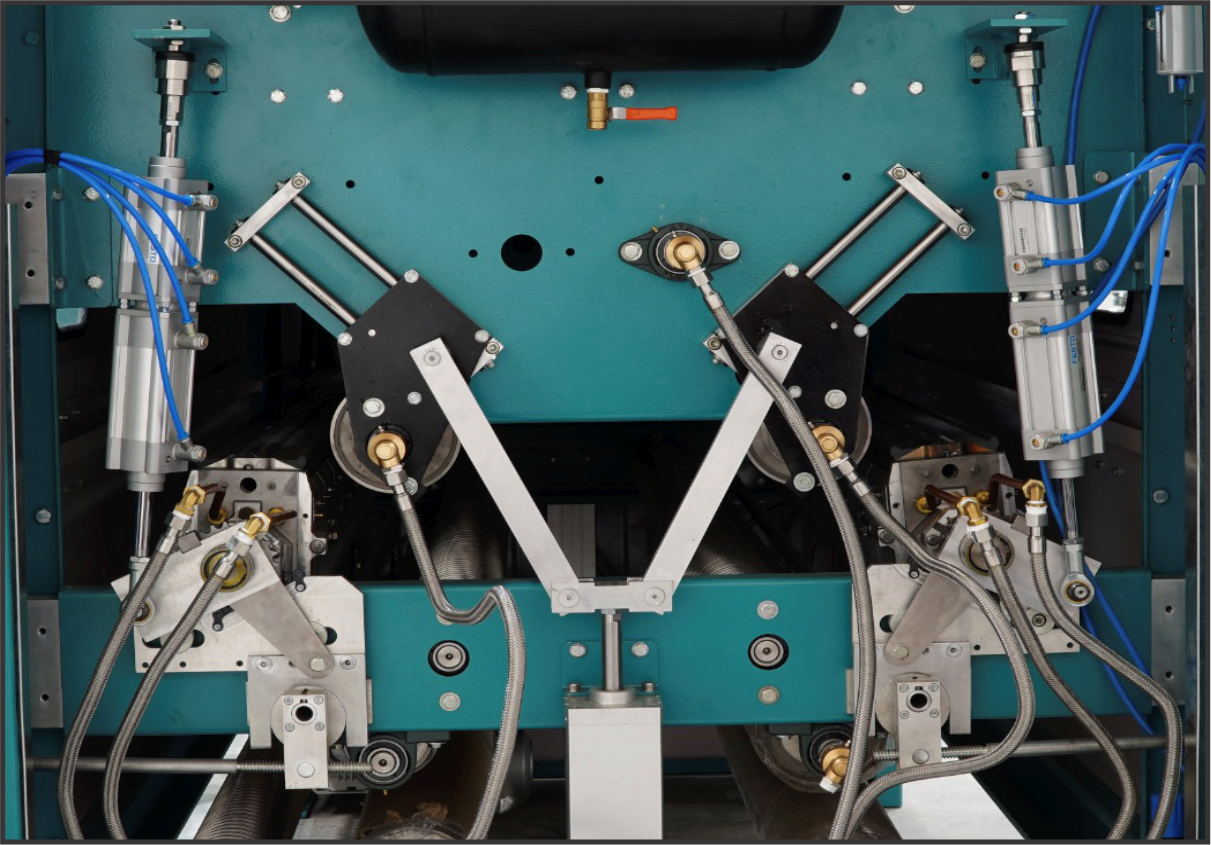

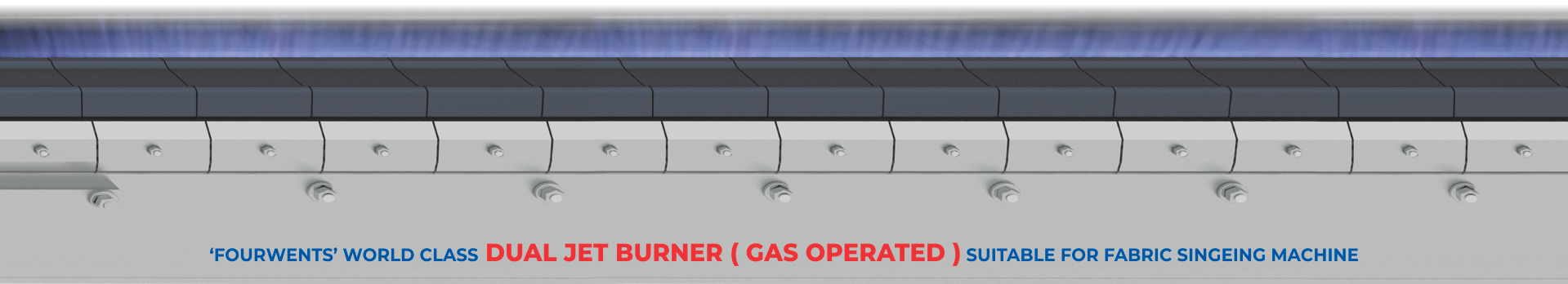

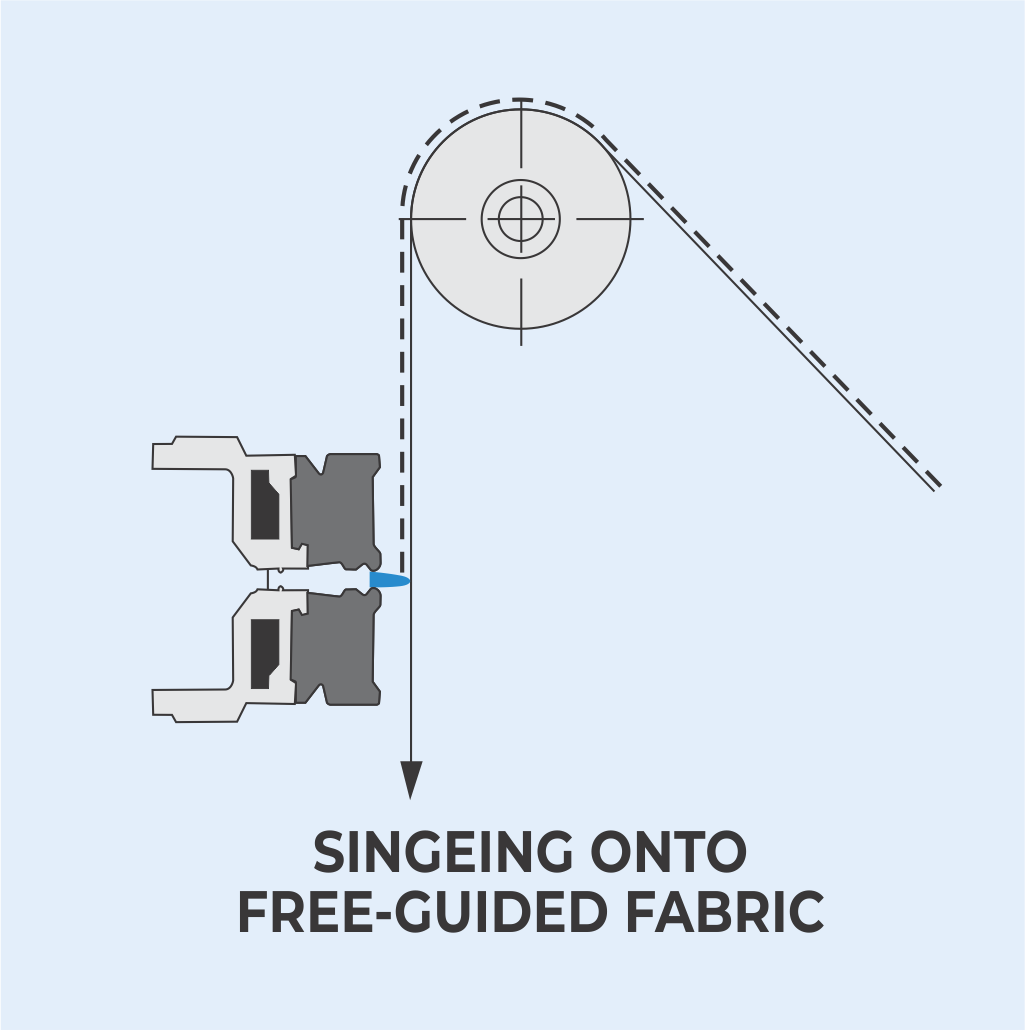

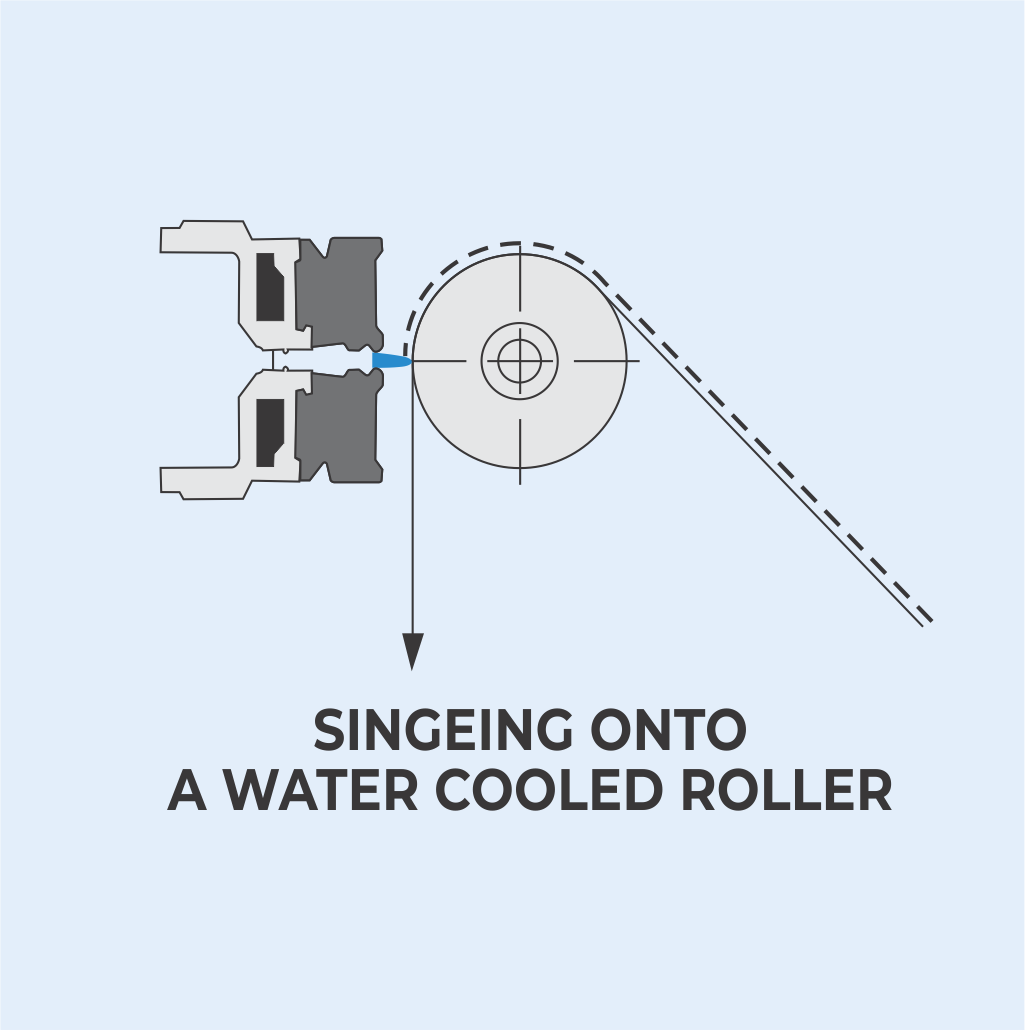

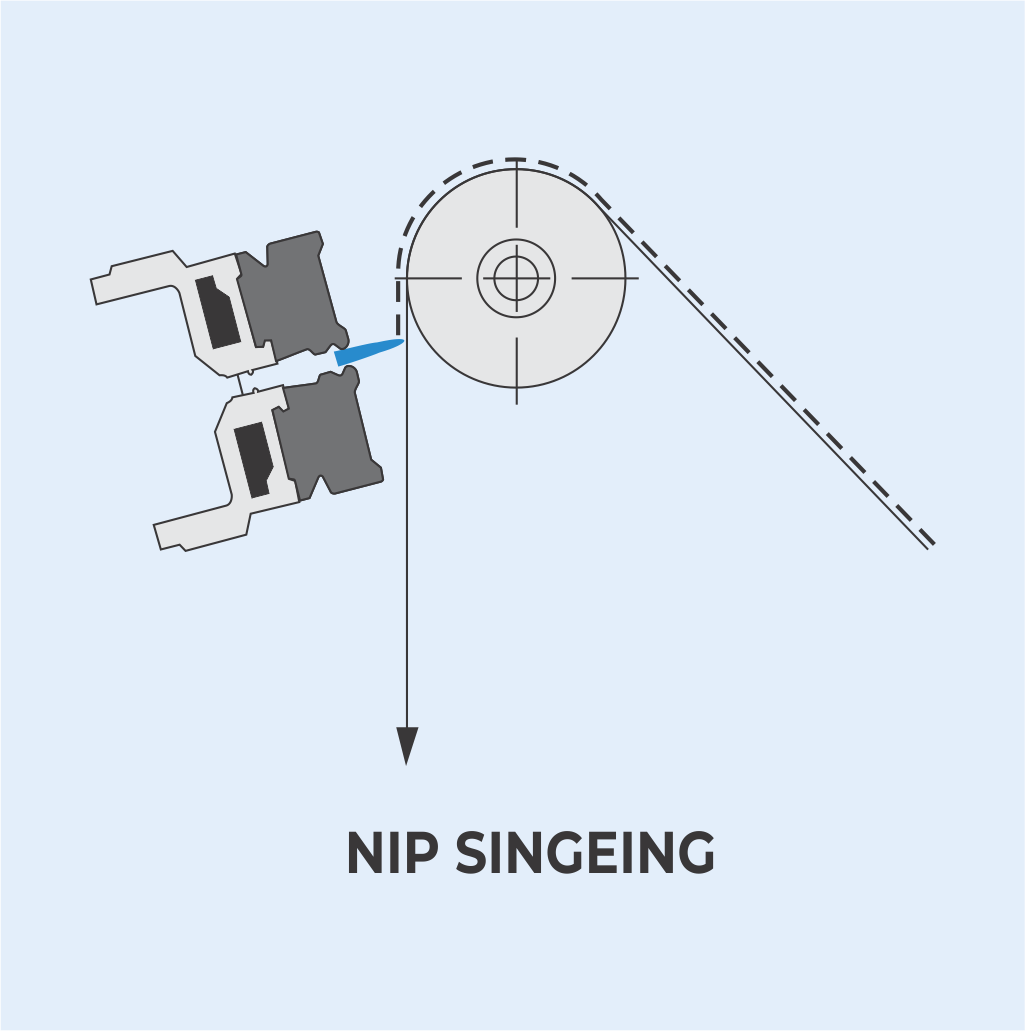

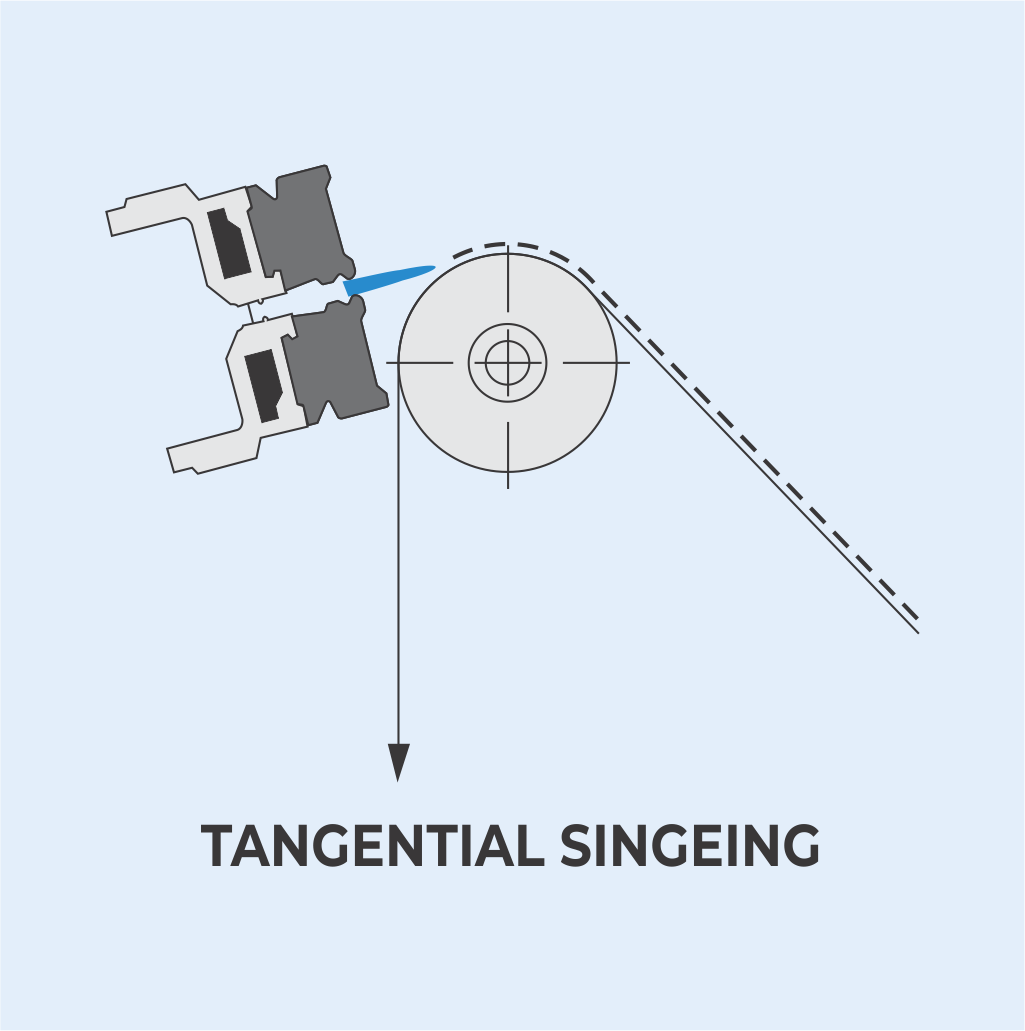

THE MACHINE IS BUILT AROUND THE TRIED-AND-TRUE COMPONENTS OF TRADITIONAL SINGE-NX SINGERS, SUCH AS BURNERS, PROPORTIONAL GAS:AIR MIXING, AND PRE-SELECTED SINGEING SETTINGS . THE MACHINE HAS THREE SINGEING LOCATIONS AND CAN SINGE THE FRONT SIDE TWICE IN ONE PASS. TANGENTIAL SINGEING, SINGEING ON THE WATER COOLED ROLLER, AND SINGEING ON THE FREE GUIDED CLOTH ARE THE THREE SINGEING POSITIONS.

LIGHTER KNITS WILL BE SINGED IN THE "SINGEING ON THE WATER COOLED ROLLER" OR "TANGENTIAL SINGEING" POSITIONS. HEAVIER MATERIALS REQUIRE MORE HEAT ENERGY AND MUST THUS BE SINGED IN POSITION "SINGEING ON THE FREE GUIDED CLOTH." THIS IS THE MOST POWERFUL SINGEING POSITION.

HE PRIMARY DISTINCTION BETWEEN SINGEING MACHINES FOR WOVEN FABRICS IS FABRIC GUIDANCE AND CONVEYANCE. THE VOCALIST HAS SELVEDGE UNCURLING AS WELL AS A MOTORISED SPREADING AND CENTERING DEVICE. A COMBINATION OF MOTORISED SCROLL ROLLERS WILL GUIDE THE OPEN STRETCHED MATERIAL, ENSURING THE BEST POSSIBLE OPENING BEFORE THE FABRIC IS SINGED. WHEN THE FLAME IS ACTIVATED, THE CLOTH IS PROTECTED BY A WATER-COOLED ROLLER. AGAIN, THE SINGEING ROLLER IS PUSHED TO PRESERVE CLOTH TENSION AS LOW AS POSSIBLE. THE SPACING BETWEEN THE VARIOUS GUIDING ROLLERS IS KEPT AS NARROW AS POSSIBLE TO PREVENT THE SELVEDGES FROM CURLING UP AGAIN. THE PERFORMER IS PERMITTED TO SINGE BOTH SIDES OF THE MATERIAL IN ONE SECTION OR, IF NOT REQUIRED, MERELY THE FACE SIDE.

FOLLOWING THE SINGEING, THE MATERIAL IS LED TO A VACUUM CLEANING MACHINE PLACED ON TOP OF THE SINGER, WHICH REMOVES ALL RESIDUES AND IMPURITIES FROM THE FRONT AND BACK SIDES. BECAUSE KNITWEAR IS SUSCEPTIBLE TO MECHANICAL ENERGY, WHICH COULD DESTROY THE FABRIC, IT WAS CHOSEN TO EMPLOY ONLY AIR UNDER PRESSURE.

A FABRIC PULL ROLLER THAT PUSHES THE FABRIC THROUGH THE MACHINE HAS BEEN PUT ON TOP OF THE SINGER. TO KEEP THE FABRIC FROM CATCHING FIRE, THE KNITWEAR IS DIRECTED INTO A STEAM BOX USING A SCROLL ROLLER. THE BOX IS COMPLETELY FILLED WITH STEAM, WHICH SETTLES ON THE FABRIC AND KEEPS IT FROM CATCHING FIRE. THE CLOTH IS FED INTO BOX CARRIAGES OR WHATEVER THE USER HAS AVAILABLE VIA A PLAITER.

THE SINGEING FLAME MEETS THE FREE GUIDED FABRIC AT RIGHT ANGLES AS THE FABRIC PASSES BETWEEN TWO GUIDE ROLLERS. THE POSITION IS SUITABLE FOR 100% NATURAL FIBERS AND FOR BLENDED FABRICS WHICH HAVE BEEN THOROUGHLY BEATEN, WITH WEIGHTS OVER 125g/m².

THE SINGEING FLAME MEETS AT RIGHT ANGLE ON TO THE FABRIC PASSING OVER A WATER COOLED ROLLER. THIS OPTION NORMALLY FOR QUALITY COMPOSED OF TEMPERATURE SENSITIVE FIBERS, OPEN-WEAVE BLENDED FABRICS AND THOSE WITH WEIGHTS OF LESS THAN 125g/m².

THE SINGEING FLAME CLOSE TO THE FABRIC, BUT JUST MISSING THE FABRIC SURFACE, SUITABLE FOR HEAVIER BLENDS OR HEAVIER SYNTHETIC FABRIC. THERE ARE OTHER PARAMETERS THAT INFLAME, IN ADDITION TO THE BURNER POSITION. (A) MACHINE SPEED. (B) FLAME INTENSITIES. (C) DISTANCE BETWEEN BURNER & FABRIC AND LASTLY (D) FABRIC TEMPERATURE.

THE SINGEING PROCESS IS RECOMMENDED FOR ALL MATERIALS WHICH CANNOT TOLERATE DIRECT EXPOSURE TO FLAME. TANGENTIAL SINGEING CAN ALSO EQUALIZE PROTRUDING FIBERS AND REPAIR FILAMENT BREAKS.

| HEATING MEDIUM | : LPG OR NATURAL GAS |

| FABRIC WIDTH | : 2400mm |

| ROLLER WIDTH | : 2600mm |

| MACHINE SPEED | : APPROX. 15 TO 150 m/min |

| MIN. SINGEING SPEED | : 25 m/min ( CONFIGURABLE ) |

| WATER PRESSURE | : 3 BAR |

| GAS PRESSURE | : 0.3 TO 3.0 BAR |

| STEAM PRESSURE: 6 BAR | : 6 BAR |

| COMPRASSED AIR | : 6 BAR |

| ELECTRIC VOLTEGE | : 400V, 3PHASE, 50HZ |