NICE APPEARANCE, GOOD SEAL, SMOKING DUST, NO LEAKAGE

2 PCS. BURNERS IN ONE SINGEING UNIT, EACH BURNER INDEPENDENT CONTROL AND OPERATION, IDEAL STRUCTURE, LESS SPACE OCCUPIED.

SCIENTIFICALLY GAS MIXING SYSTEM, MAKE SURE CONSTANT MIXING RATIO BETWEEN GAS AND AIR, HIGHEST FLAME TEMPERATURE, PRESSURE PERFECT SINGEING PERFORMANCE.

TANGENTIAL SINGED ON GUIDE ROLL, SINGED ONTO FREE GUIDED FABRIC IN VERTICAL, SINGED ONTO FREE FABRIC IN ANGLE LESS 90°, SINGED ONTO COOLED GUIDE ROLL SUITABLE FOR VARIOUS FABRICS.

TOUCH SCREEN AND BUTTON OPERATION, AUTO CONTROL, AUTO MONITOR, AUTO ALARM AND MAINTENANCE HINT.

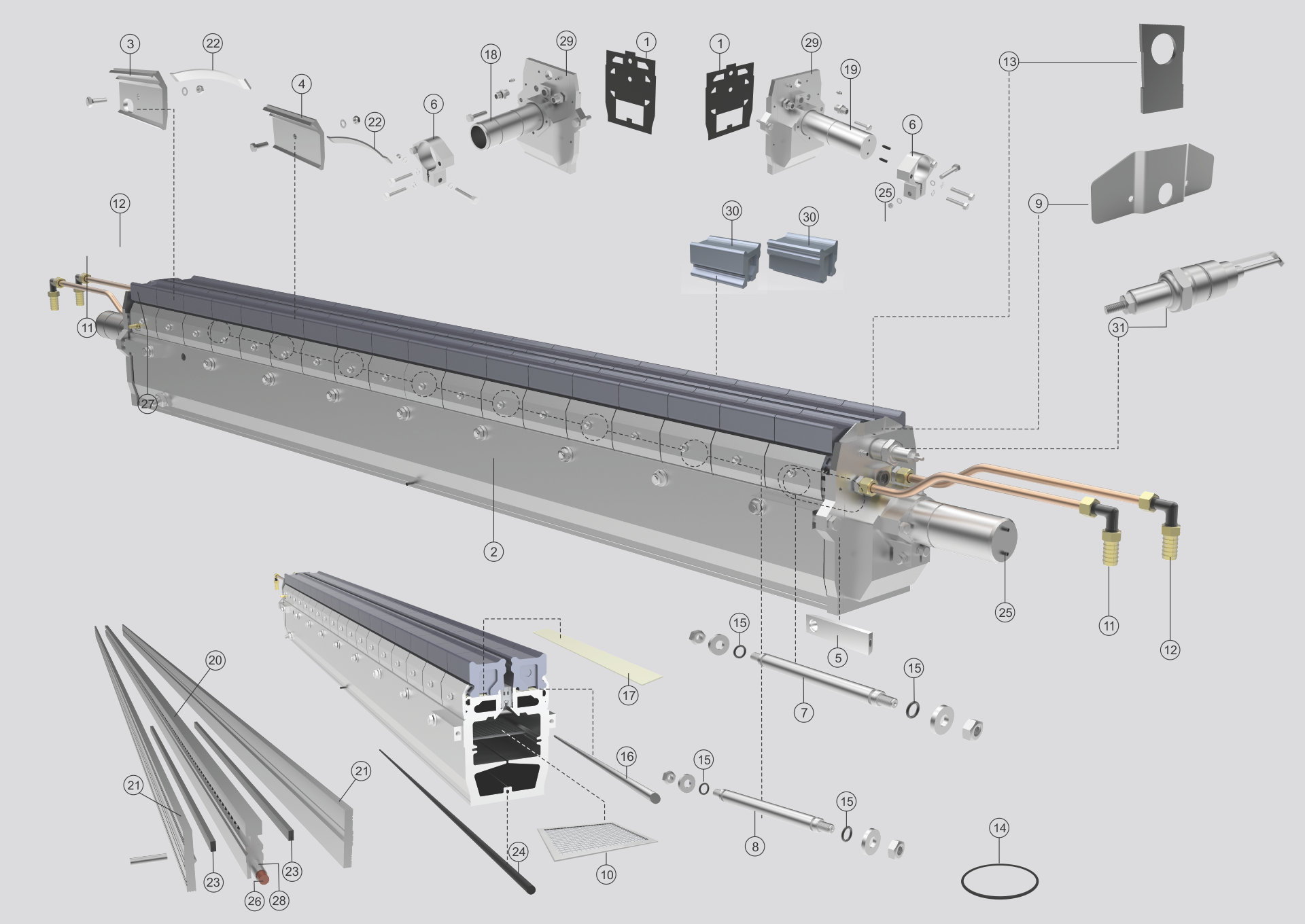

| POS. NO. |

DESCRIPTION OF ITEMS | QUANTITY REQUIRED / BURNER LENGTH | ||||||

|---|---|---|---|---|---|---|---|---|

| 1800 MM | 2000 MM | 2200 MM | 2400 MM | 2600 MM | 3400 MM | 3600 MM | ||

| 1 | FLANGE GASKET | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 2 | BURNER BODY | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 3 | CLAMP PLATE (WITH SLOT) | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 4 | CLAMP PLATE (WITHOUT SLOT) | 34 | 38 | 42 | 46 | 50 | 66 | 70 |

| 5 | SUPPORT (25x15x110) | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| 6 | FIXING FLANGE | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 7 | THREADED BOLT SHORT | 7 | 8 | 9 | 10 | 11 | 15 | 16 |

| 8 | THREADED BOLT LONG | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 9 | FLAME SHIELDING PLATE | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 10 | FLAT FILTER | 18 | 20 | 22 | 24 | 26 | 34 | 36 |

| 11 | INLET PIPE SMALL | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 12 | INLET PIPE LONG | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 13 | SEALING SET | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 14 | CFT 'O' RING | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 15 | O' RING (I.D.11 x Ø2.5) | 18 | 20 | 22 | 24 | 26 | 34 | 36 |

| 16 | ROUND ROD (Ø3x200) | 18 | 20 | 22 | 24 | 26 | 34 | 36 |

| 17 | SUPER WOOL ISOLATION STRIP (39x2x400) | 9 | 10 | 11 | 12 | 13 | 17 | 18 |

| 18 | SHAFT END - 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| 19 | SHAFT END - 2 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

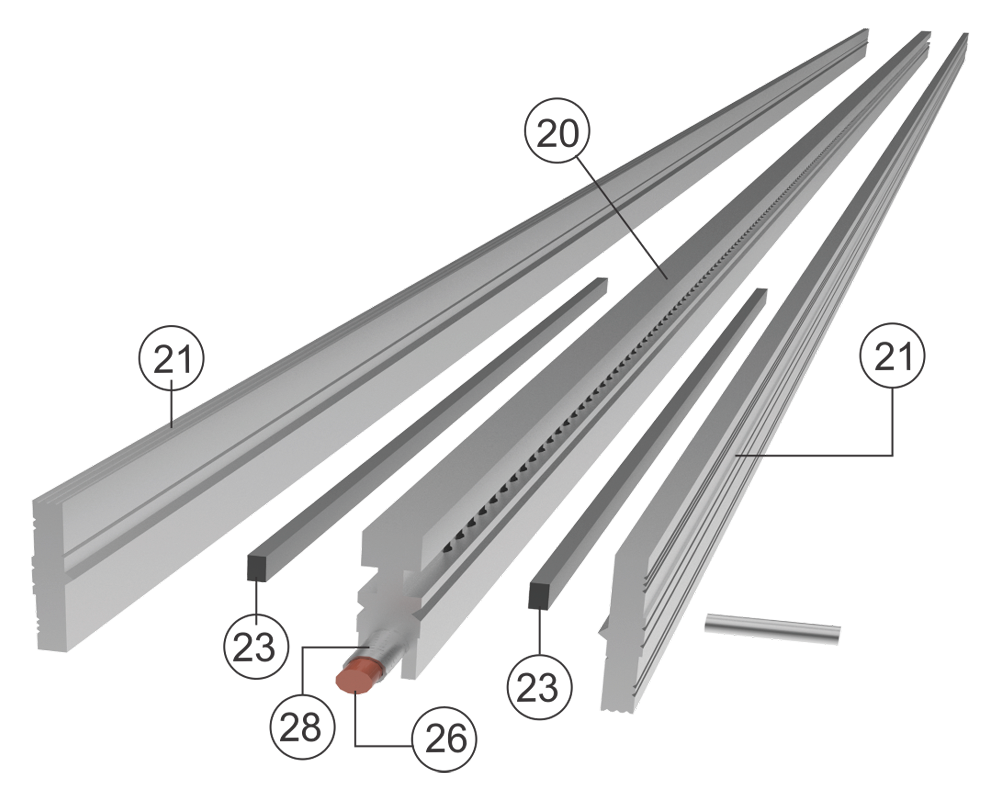

| 20 | BURNER MIDDLE RAIL (33.5x10x1796) | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| 21 | BURNER SIDE RAIL (36x7x1796) | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 22 | SPRING STEEL STRIP | 36 | 40 | 44 | 48 | 52 | 68 | 72 |

| 23 | GASKET (3x6x285) | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| 24 | RUBBER CORD (Ø6x1800) | 1800 MM |

2000 MM |

2200 MM |

2400 MM |

2600 MM |

3400 MM |

3600 MM |

| 25 | GRUB SCREW (M8x25) | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 26 | SILICON RUBBER CORD FOR GAS SPRING | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| 27 | VENT SCREW - 1/8" | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 28 | SPRING L-285 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 29 | BURNER FLANGE | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 30 | CERAMIC BRICKS / RAMP BODY | 36 | 40 | 44 | 48 | 52 | 68 | 72 |

| 31 | SPARK PLUG | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

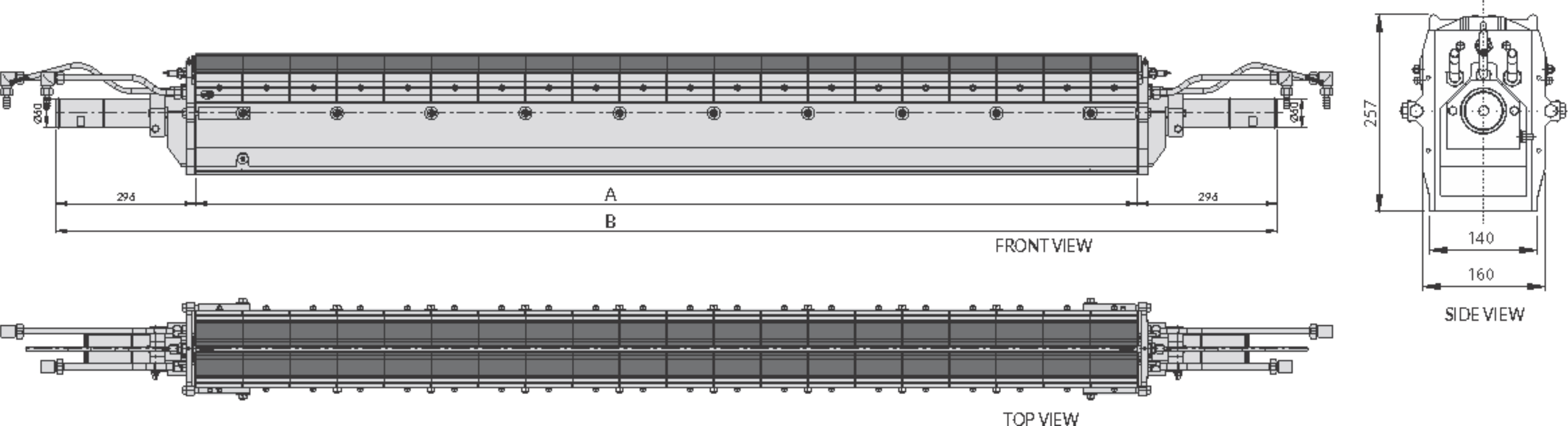

| BURNER WIDTH | W/W | A | B |

|---|---|---|---|

| 1800 mm | 1600 mm | 1800 | 2392 |

| 2000 mm | 1800 mm | 2000 | 2876 |

| 2200 mm | 2000 mm | 2200 | 3076 |

| 2400 mm | 2200 mm | 2400 | 3276 |

| 3000 mm | 2800 mm | 3000 | 3876 |

| 3200 mm | 3000 mm | 3200 | 4076 |

| 3400 mm | 3200 mm | 3400 | 4376 |

| 3600 mm | 3400 mm | 3600 | 4192 |

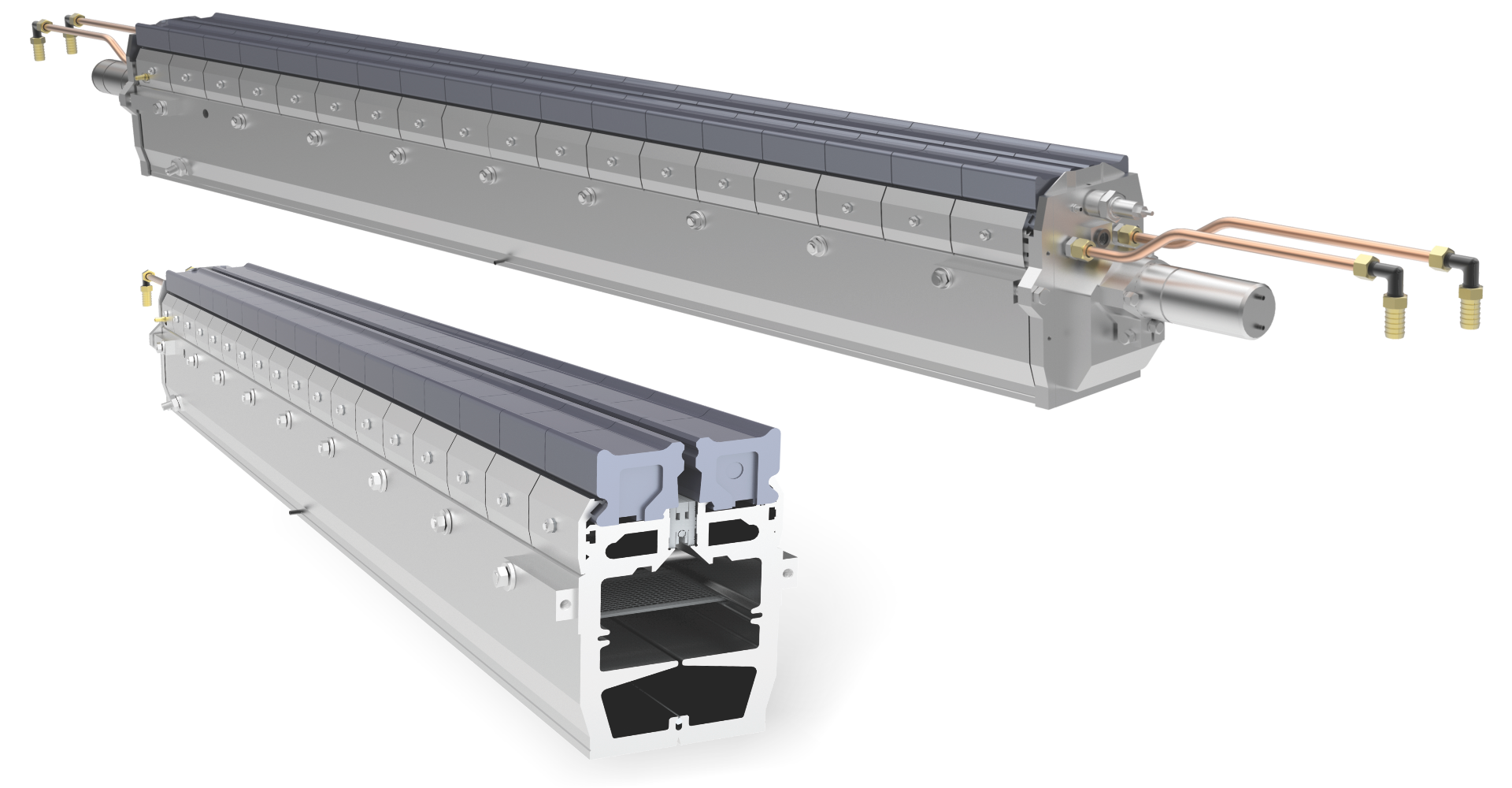

DUAL-JET BURNER COMPLETE ASSEMBLY EQUIPPED WITH HIGH HEAT RESISTING CERAMIC RAMP/ BRICKS BODY FITTED WITH BURNER FLANGES SUPPORTING TUBES AND COOLING WATER CONNECTION.

READY ASSEMBLED FOR AN INSTALLATION INTO THE EXISTING FABRIC SINGEING MACHINES.

| BURNER LENGTH | 2000/1800 mm |

| BURNER LENGTH | 2200/2000 mm |

| BURNER LENGTH | 2400/2200 mm |

| BURNER LENGTH | 2600/2400 mm |

| BURNER LENGTH | 3400/3200 mm |

| BURNER LENGTH | 3600/3400 mm |

SUITABLE FOR SINGE-NX & OSTHOFF

DUAL-JET GAS SINGEING MACHINES

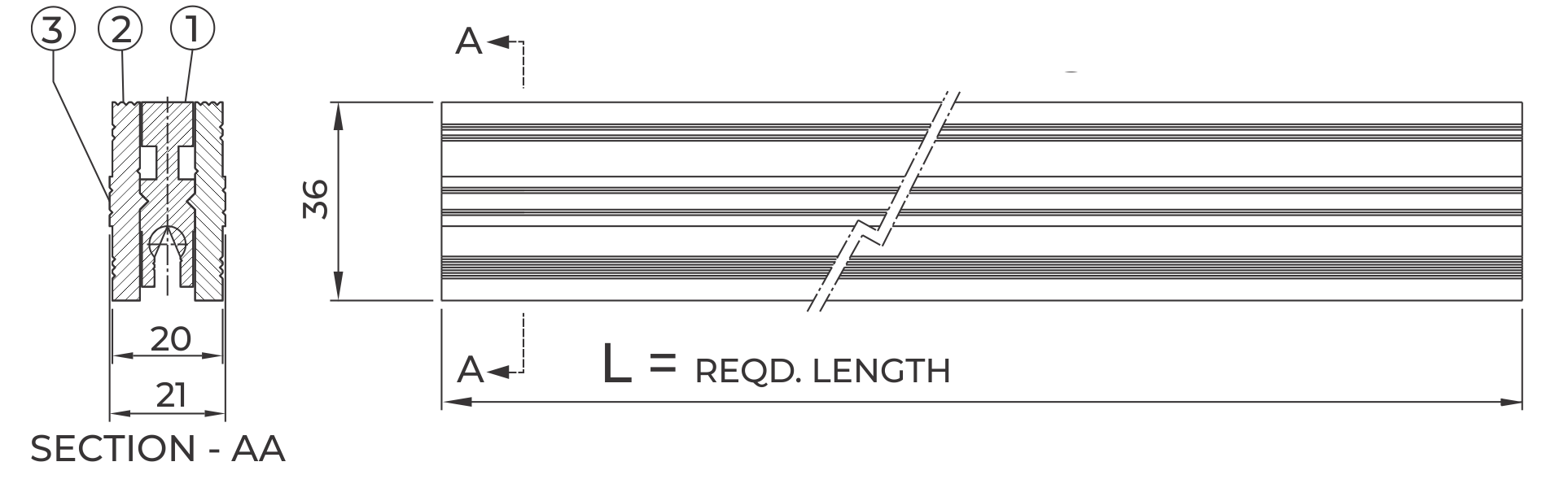

| SR. NO | BURNER LENGTH | L= REQD. LENGTH |

|---|---|---|

| 1 | 2000/1800 mm | 1997 mm |

| 2 | 2200/2000 mm | 2197 mm |

| 3 | 2400/2200 mm | 2397 mm |

| 4 | 2600/2400 mm | 2597 mm |

| 5 | 3400/3200 mm | 3397 mm |

| 6 | 3600/3400 mm | 3597 mm |